Introduction

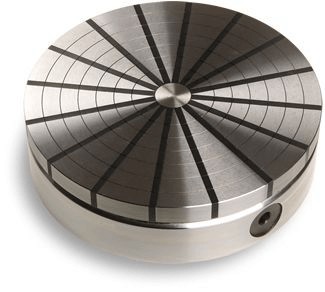

Magnetic chucks are an essential tool in the manufacturing industry. They are used to hold workpieces securely in place during machining operations such as grinding, milling, and drilling. A magnetic chuck is a device that uses magnetic fields to hold a workpiece in place. It is a simple and effective way to hold a workpiece without the need for clamps or other mechanical devices. Magnetic chucks are used in a wide range of industries, including metalworking, woodworking, electronics, and automotive.

Types of Magnetic Chucks

There are three main types of magnetic chucks: permanent magnetic chucks, electromagnetic chucks, and electro-permanent magnetic chucks. Permanent magnetic chucks use permanent magnets to generate a magnetic field. Electromagnetic chucks use an electrical current to generate a magnetic field. Electro-permanent magnetic chucks combine the advantages of both permanent magnetic chucks and electromagnetic chucks.

Advantages of Magnetic Chucks

Magnetic chucks offer several advantages over other types of workholding devices. They have a high holding power, which means they can hold even heavy workpieces securely in place. They are also easy to operate, with no need for clamps or other mechanical devices. Magnetic chucks are suitable for a wide range of workpiece shapes and sizes, and they cause minimal deformation of the workpiece.

How Magnetic Chucks Work

Magnetic chucks work by generating a magnetic field that holds the workpiece in place. The magnetic field is created by the interaction of magnetic fields from the chuck and the workpiece. The chuck generates a magnetic field that attracts the workpiece, holding it in place. The strength of the magnetic field depends on the type of magnetic chuck and the size of the workpiece.

Factors to Consider When Choosing a Magnetic Chuck

When choosing a magnetic chuck, several factors need to be considered. The size and shape of the workpiece are important, as different types of magnetic chucks are suitable for different workpiece sizes and shapes. The type of machining operation is also important, as some types of magnetic chucks are better suited for certain types of machining operations. The size and strength of the magnetic chuck are also important, as they determine the holding power of the chuck. Finally, the power supply requirements of the magnetic chuck need to be considered.

Maintenance and Care of Magnetic Chucks

Magnetic chucks require regular maintenance and care to ensure they continue to function properly. They should be cleaned and inspected regularly to ensure there is no damage to the chuck surface. Lubrication is also important to ensure the chuck operates smoothly. When not in use, magnetic chucks should be stored in a dry and clean environment.

Common Problems with Magnetic Chucks and How to Fix Them

Common problems with magnetic chucks include loss of holding power, uneven holding, and damage to the magnetic chuck surface. These problems can be caused by a variety of factors, including improper maintenance, incorrect use, and damage to the chuck surface. Solutions to these problems include cleaning and inspection, proper use and maintenance, and repair or replacement of damaged parts.

Safety Precautions When Using Magnetic Chucks

When using magnetic chucks, several safety precautions need to be taken. Proper grounding is essential to prevent electrical shock. Contact with the magnetic chuck surface should be avoided, as it can cause injury or damage to the workpiece. Workpieces should be handled carefully to avoid damage to the chuck surface.

Applications of Magnetic Chucks in Different Industries

Magnetic chucks are used in a wide range of industries, including metalworking, woodworking, electronics, and automotive. In metalworking, they are used for grinding, milling, and drilling operations. In woodworking, they are used for planing and sanding operations. In electronics, they are used for precision machining operations. In automotive, they are used for engine and transmission machining operations.

Future Developments in Magnetic Chuck Technology

Future developments in magnetic chuck technology are focused on advancements in magnetic materials, integration with automation systems, and improved holding power and accuracy. Advancements in magnetic materials will allow for stronger and more efficient magnetic chucks. Integration with automation systems will allow for more efficient and precise machining operations. Improved holding power and accuracy will allow for more complex machining operations.

Conclusion

Magnetic chucks are an essential tool in modern manufacturing. They offer several advantages over other types of workholding devices, including high holding power, easy operation, and suitability for a wide range of workpiece shapes and sizes. When choosing a magnetic chuck, several factors need to be considered, including workpiece size and shape, type of machining operation, magnetic chuck size and strength, and power supply requirements. Proper maintenance and care are essential to ensure magnetic chucks continue to function properly. Future developments in magnetic chuck technology will focus on advancements in magnetic materials, integration with automation systems, and improved holding power and accuracy.