Introduction

Clamping magnets are a versatile and efficient tool used in a variety of industries, from manufacturing to DIY projects. They are designed to hold and secure objects in place, making them an essential tool for many applications. The versatility of clamping magnets is what makes them so valuable, as they can be used in a wide range of applications. In this article, we will explore the different types of clamping magnets, their uses, benefits, and safety considerations.

Introduction to Clamping Magnets: What Are They and How Do They Work?

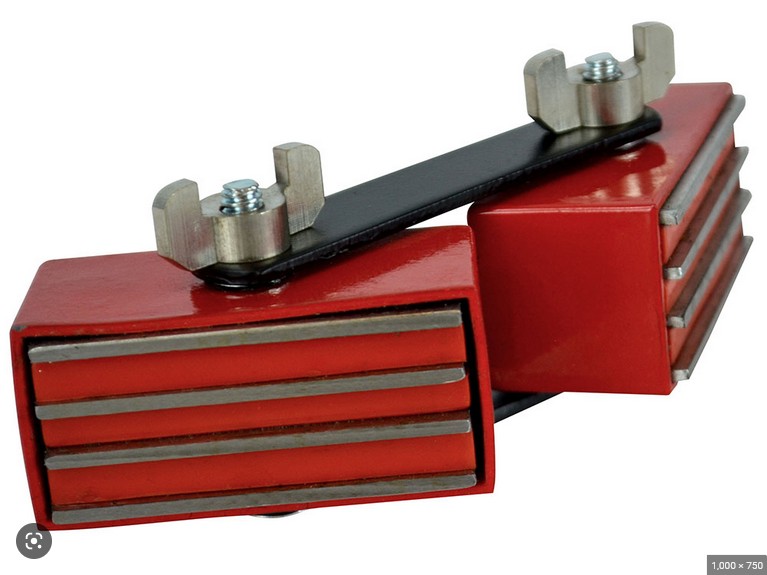

Clamping magnets are devices that use magnetic force to hold and secure objects in place. They work by creating a magnetic field that attracts ferromagnetic materials, such as iron or steel. The strength of the magnetic field depends on the strength of the magnet and the distance between the magnet and the object being held.

There are several types of clamping magnets, including permanent, electromagnetic, and hybrid varieties. Permanent magnets are made of materials that retain their magnetic properties, such as neodymium or samarium cobalt. Electromagnetic magnets use an electric current to create a magnetic field, while hybrid magnets combine the properties of both permanent and electromagnetic magnets.

DIY Applications of Clamping Magnets: Creative Uses for Home and Hobby Projects

Clamping magnets are a popular tool for DIY projects, as they can be used to hold and secure objects in place while working on them. For example, they can be used to hold a piece of metal in place while welding or to hold a piece of wood in place while drilling. They can also be used to create magnetic tool holders or to hold objects in place while painting.

One of the benefits of using clamping magnets for DIY projects is their versatility. They can be used in a wide range of applications, making them a valuable tool for any DIY enthusiast. They are also easy to use and can be quickly attached and detached from objects.

Industrial and Manufacturing Uses of Clamping Magnets: Heavy-Duty Applications in Production

Clamping magnets are also used in industrial and manufacturing applications, where they are used to hold and secure objects during production processes. For example, they can be used to hold metal sheets in place while cutting or to hold parts in place during assembly. They are also used in welding and machining applications.

One of the benefits of using clamping magnets in industrial and manufacturing applications is their efficiency. They can hold objects in place quickly and securely, reducing the time and effort required for production processes. They are also cost-effective, as they can be reused multiple times.

Benefits of Using Clamping Magnets: Efficiency, Versatility, and Cost-Effectiveness

The benefits of using clamping magnets include their efficiency, versatility, and cost-effectiveness. They can hold objects in place quickly and securely, reducing the time and effort required for production processes. They are also versatile, as they can be used in a wide range of applications. Finally, they are cost-effective, as they can be reused multiple times.

Types of Clamping Magnets: Permanent, Electromagnetic, and Hybrid Varieties

There are several types of clamping magnets, including permanent, electromagnetic, and hybrid varieties. Permanent magnets are made of materials that retain their magnetic properties, such as neodymium or samarium cobalt. Electromagnetic magnets use an electric current to create a magnetic field, while hybrid magnets combine the properties of both permanent and electromagnetic magnets.

Each type of clamping magnet has its advantages and disadvantages. For example, permanent magnets are strong and durable but cannot be turned on or off. Electromagnetic magnets can be turned on and off but require an electric current to function. Hybrid magnets combine the properties of both permanent and electromagnetic magnets, offering the best of both worlds.

Choosing the Right Clamping Magnet: Factors to Consider for Your Specific Needs

When choosing a clamping magnet, there are several factors to consider, including the strength of the magnet, the size and weight of the object being held, and the environment in which the magnet will be used. The strength of the magnet should be sufficient to hold the object in place, while the size and weight of the object should be within the magnet’s capacity.

It is also important to consider the environment in which the magnet will be used. For example, if the magnet will be used in a high-temperature environment, it should be made of materials that can withstand high temperatures.

Safety Considerations When Using Clamping Magnets: Precautions to Take for Safe Operation

When using clamping magnets, it is important to take safety precautions to ensure safe operation. For example, magnets should be kept away from electronic devices and credit cards, as they can cause damage. They should also be kept away from pacemakers and other medical devices.

It is also important to handle magnets with care, as they can be dangerous if mishandled. They should be kept away from children and pets, and should not be dropped or thrown.

Maintenance and Care of Clamping Magnets: Tips for Keeping Them in Good Condition

To keep clamping magnets in good condition, it is important to clean them regularly and store them properly. They should be cleaned with a soft cloth and mild detergent, and should be stored in a dry, cool place.

It is also important to inspect magnets regularly for damage or wear. If a magnet is damaged or worn, it should be replaced immediately.

Case Studies: Real-World Examples of Clamping Magnets in Action

There are many examples of clamping magnets in use, from DIY projects to industrial applications. For example, clamping magnets are used in the automotive industry to hold metal parts in place during production processes. They are also used in the construction industry to hold metal sheets in place while cutting.

In DIY projects, clamping magnets are used to hold objects in place while working on them. For example, they can be used to hold a piece of wood in place while drilling or to hold a piece of metal in place while welding.

Future Developments in Clamping Magnet Technology: Innovations and Advancements to Watch For

There are several upcoming advancements in clamping magnet technology, including the development of stronger and more efficient magnets. These advancements will improve the versatility and efficiency of clamping magnets, making them even more valuable in a wide range of applications.

Conclusion

Clamping magnets are a versatile and efficient tool used in a wide range of applications, from DIY projects to industrial production processes. They offer many benefits, including efficiency, versatility, and cost-effectiveness. When choosing a clamping magnet, it is important to consider the strength of the magnet, the size and weight of the object being held, and the environment in which the magnet will be used. By taking safety precautions and maintaining clamping magnets properly, they can provide years of reliable service.